CNC Experiments

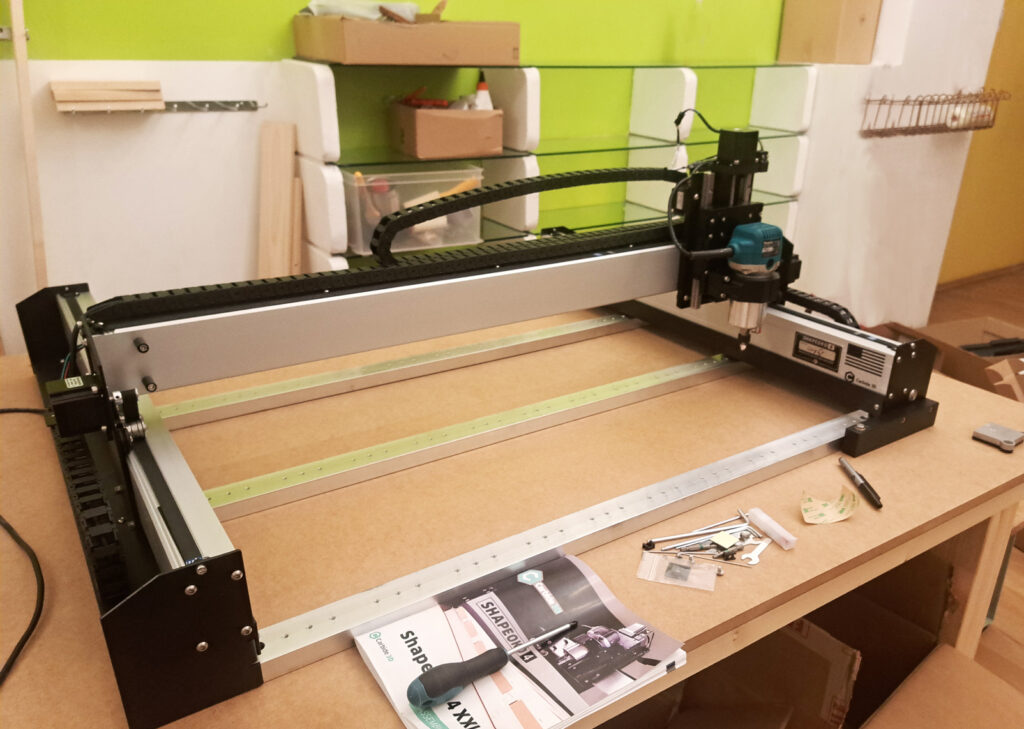

To create personalized controllers, I acquired a Shapeoko CNC machine capable of working with various materials like wood and acrylics. Combining this with a laser cutter, I engraved text onto the wooden surfaces. Additionally, I utilized the machine to craft intricate components for small furniture items.

To further enhance my projects, I also explored the integration of electronics with the wooden interfaces. This combination would add an extra layer of functionality to my custom controllers, elevating their design and utility. It is my goal to blend the warmth of natural materials with the sophistication of modern electronics.

The Shapeoko 4 XXL is a powerful desktop CNC machine that allows both hobbyists and professionals to create intricate projects. However, setting up this impressive machine requires some thought and effort.

The Shapeoko is a large machine, and it requires a strong, stable surface to operate effectively. Building a custom wooden table provided the ideal foundation for the CNC machine. Here’s what I needed to consider:

High density MDF for the tabletop for durability and excellent vibration absorption.

Reinforcement of the table with sturdy legs and cross-bracing. This will help to keep the table stable and reduce the chance of movement during operation.

Dimensions of the table. Ensuring that there’s enough space to accommodate the entire CNC, as well as any additional equipment I may need.

Noise during operation – which could be a concern for the neighbors. Therefore the idea is, in addition to adding rubber feet to machine, building a soundproof enclosure.

Adequate lighting – an LED strip and webcam will be placed inside the enclosure for optimal safety and precision.